PHYSICAL MODEL TESTING

BETE Spray Laboratory

Physical Model Testing

Model tests may include flow visualization in pipes, ducts, and tanks and applications-based testing to measure the effect of a spray in a system. These include impact, coating uniformity, reach, wind drift, and wall impingement. When running a model at actual process conditions isn’t practical, we use scaling parameters to relate model results to full-scale results. At times, a comparison of the laboratory model to a CFD model of the laboratory setup may be ideal for validating the CFD model of the full-scale system.

Examples of Physical Modeling Tests:

- Study of erosion patterns in fluidized beds

- Mixing of gas in a pipeline

- Pattern distribution of fire protection nozzles with simulated wind

- The spatial concentration of respirable droplets

- Comparison of flow rates and spray patterns using oil and water

- Effectiveness of tank cleaning nozzles

- Seal leak tests to ASTM A515 using Helium

- Solids buildup (“bearding”) on air-atomizing nozzles

- Life cycle testing

- Pressure vessel strain gauge testing

- Hydrostatic testing

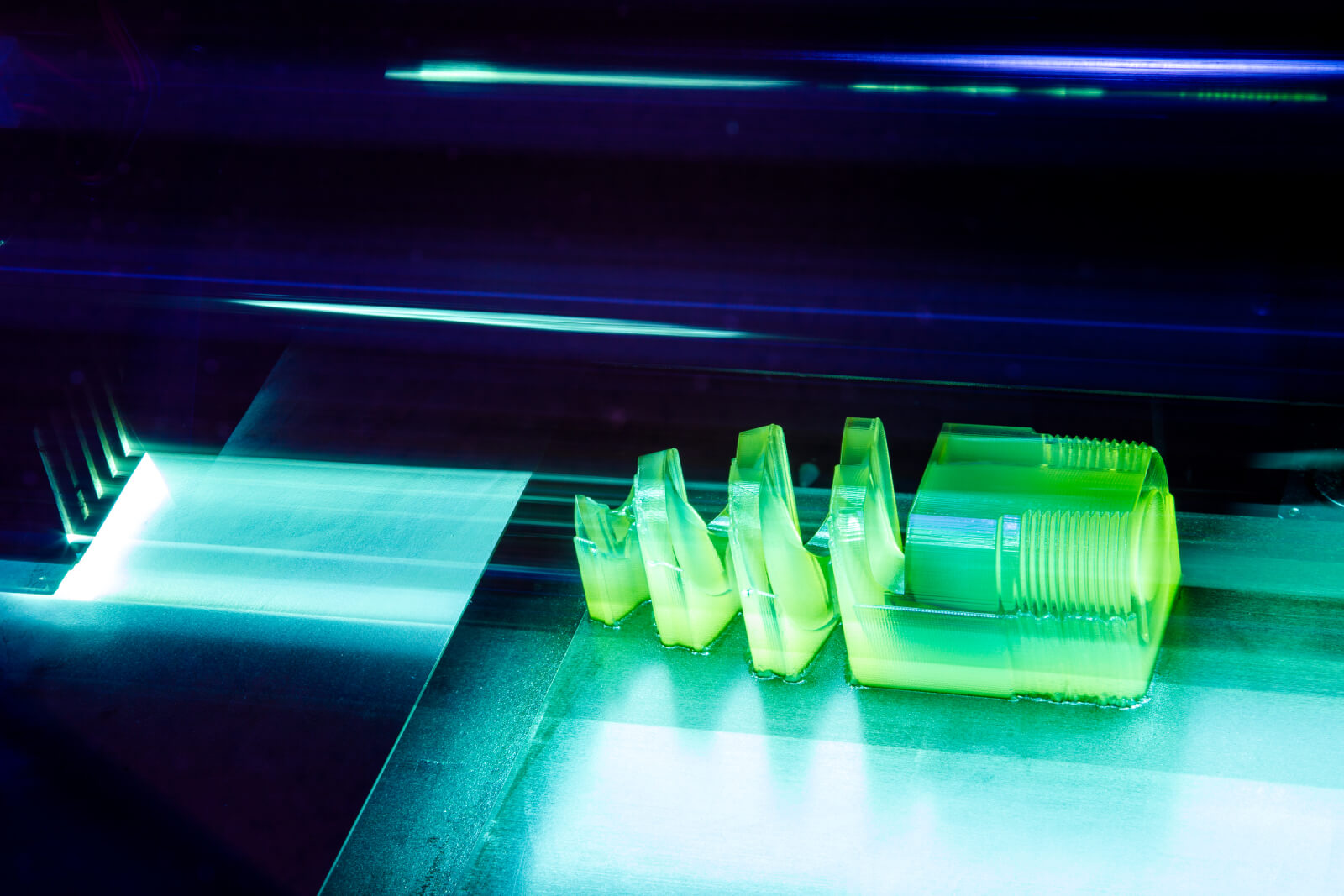

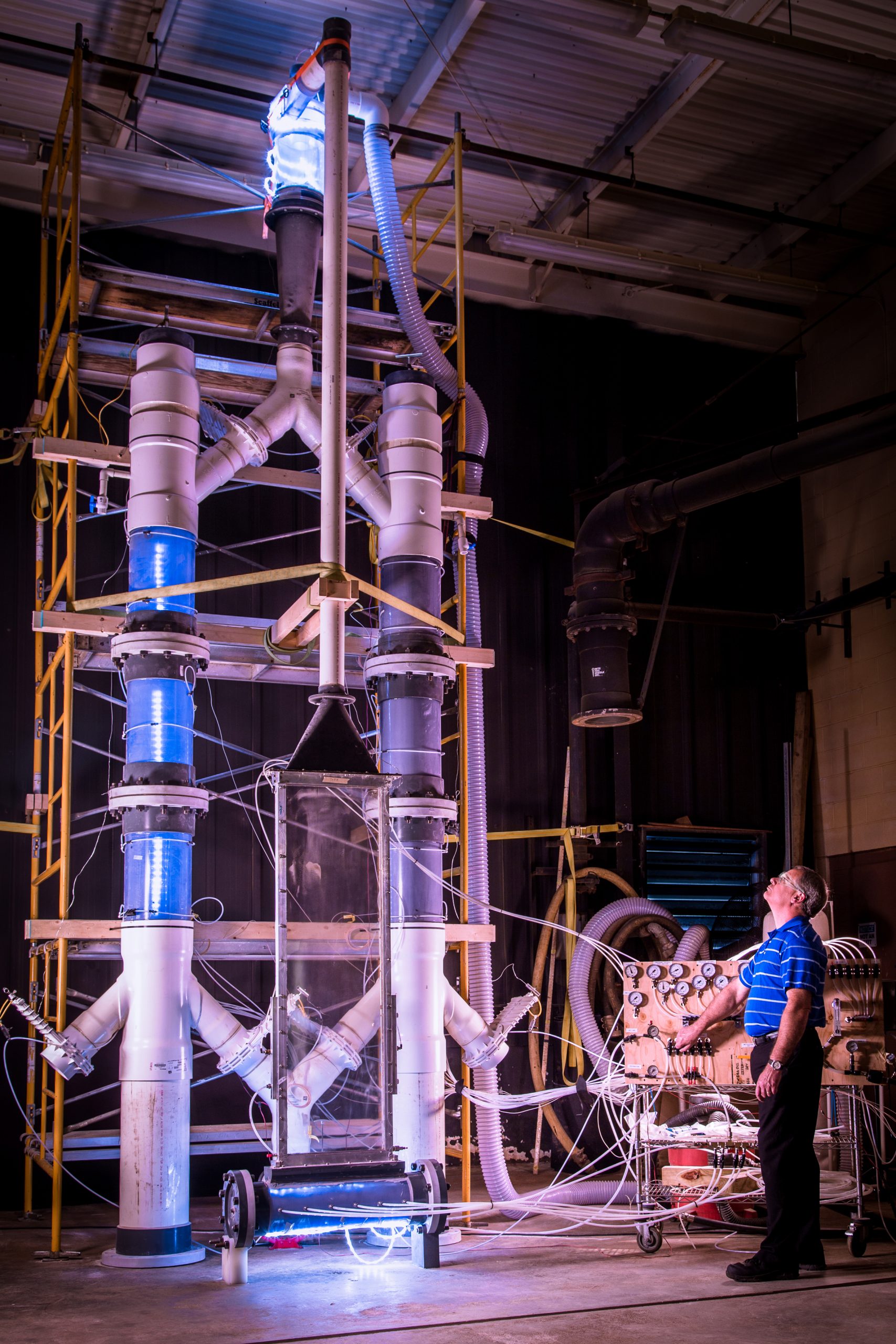

BETE can design, fabricate, instrument, and operate even large test setups such as the one illustrated here. If you need something evaluated, BETE can help you find a way to measure it.

Prototyping

BETE maintains a machine department dedicated to nozzle and manufacturing process development. Machining capabilities include multiple CNC and manual lathes and mills. Our rapid prototype machine has a 13.8” x 13.8” x 7.9” (350 X 350 X 200 mm) build volume and is capable of building intricate shapes in a variety of rigid and flexible plastics. BETE’s welding capabilities allow us to fabricate nearly any type of nozzle or assembly in virtually any material.