Exair Compressed Air Products

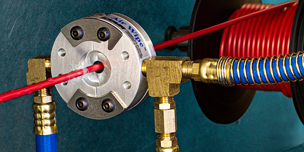

EXAIR, founded in 1983, manufactures compressed air-operated products to solve problems in industrial plants. These products are expertly engineered to reduce air consumption and increase safety, exceeding OSHA and CE standards while also complying with RoHS and REACH where applicable.

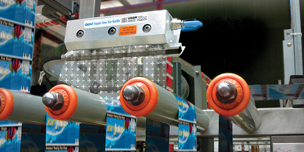

EXAIR products include: Air Knives, Cabinet Cooler Systems, engineered Air Nozzles & Jets, Industrial Vacuums, Vortex Tubes & Spot Coolers, Air Amplifiers, pneumatic conveyors, vacuum generators, and ionizing products for static elimination.

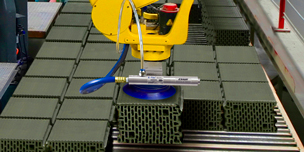

Prioritize safety and minimize maintenance with EXAIR E-Vac® Vacuum Generators. These effective suction tools provide instantaneous response for reliable pick and place operations in your facility. Available in a variety of flows and sizes to meet unique production needs.

Learn about compressed air product applications.

- Cooling

- Cleaning

- Coating

- Conveying

- Drying

- and more